News

Industrial

MEMS sensor - the core of the drone

The market size and scope of drones continues to flourish and new applications continue to emerge. The use of drones is also becoming more common, whether it is delivering mail or parcels, providing entertainment for children and the elderly, security monitoring, agricultural or industrial management, or opening up new horizons in aerial photography.

Initially, most drones were relatively simple toys. Recently, however, its flight capabilities have increased significantly, making it safer, more stable, and easier to control, enabling it to be used in a wider range of real-life applications.

One of the key factors for this improvement is the use of high performance microelectromechanical systems (MEMS) sensors. And the drone sensor market is growing rapidly:

According to IHS Markit (Consumer and Mobile Device Motion Sensors - 2017), the market for MEMS motion sensors (ie accelerometers, gyroscopes, IMUs and pressure sensors) in drones and toy helicopters is expected to reach 2021 by 2021. About 70 million units, and its 2018 to 2021 compound annual growth rate can reach 17%.

Influence of MEMS sensors on flight performance of drones

Thanks to the use of inertial MEMS sensors, the drone ensures that its direction is stable and can be precisely controlled by the user or even autonomous. However, some challenges have made the design of the UAV system very complicated. For example, the motor is not perfectly calibrated, the system dynamics may vary according to the payload, the operating conditions may be abrupt, or the sensor may be in error. These challenges can cause misalignment in the positioning process and ultimately lead to positional deviations during navigation and even to the failure of the drone.

High-quality MEMS sensors and advanced software are essential to make drones beyond the reach of toys. The accuracy of the UAV's inertial measurement unit (IMU), air pressure sensor, geomagnetic sensor, application-specific sensor node (ASSN) and sensor data fusion has a direct and substantial impact on flight performance.

Size constraints and harsh environmental and operating conditions (such as temperature changes and vibration) take the sensor requirements to a new level. MEMS sensors must avoid these effects as much as possible and provide accurate, reliable measurements.

There are several ways to achieve superior flight performance: software algorithms such as sensor calibration and data fusion; mechanical system design, such as reducing vibration, and selecting MEMS sensors based on drone manufacturers' own requirements and needs. Let's take a closer look at the MEMS sensor and refer to some examples.

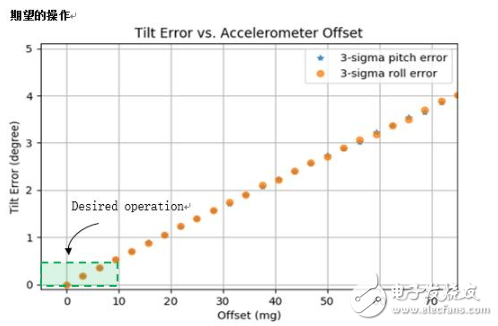

At the heart of the drone is its Attitude Heading Reference System (AHRS), which includes inertial sensors, magnetometers and processing units. AHRS estimates device positioning, such as roll, pitch, and yaw angles. Sensor errors such as offset, sensitivity errors, or thermal drift can cause positioning errors. Figure 1 shows the positioning error (rolling, pitch angle) in the form of an accelerometer offset function, which is often the core source of continuous sensor error. For example, an offset of only 20 mg of accelerometer will cause a 1 degree error in the direction of the device.

Figure 1: Tilt error due to accelerometer offset

Inertial Measurement Unit (IMU)

The IMU includes accelerometers and gyroscopes, as well as corresponding embedded handlers. This makes it possible to recognize motion in terms of linear movement and rotation.

Air pressure sensor

The high-performance air pressure sensor built into the drone accurately measures altitude and is used in conjunction with the IMU's altitude control readings. The air pressure sensor must avoid external influences and inaccuracies as much as possible.

Today, with additional sensors such as GPS and optical flow, distance sensors can be used to increase system reliability and reduce positional errors.

The requirements for pressure sensors in drones are often very demanding. Due to the adverse weather and temperature conditions, the high accuracy must be kept within tight tolerances, and the sensor must have low retardation and very low drift over long periods of time.

In addition to TCO improvements, there are a number of factors that contribute to overall accuracy: relative accuracy, noise, stability, and absolute accuracy. From clumsy toys to high-precision aircraft; as long as engineers want it, the potential for innovative industrial and commercial drones can be said to be endless.

Magnetometer

The magnetometer, like the same compass, can achieve the heading of the drone based on the Earth's magnetic field.

Application specific sensor node

The Application Specific Sensor Node (ASSN) provides a highly integrated smart sensor hub that combines multiple sensors in a single package with a programmable microcontroller. It provides a flexible, low-power solution for motion sensing applications.

Signal processing and software

In addition to the individual sensors, we can also view the overall signal processing structure of the drone at the system level and determine the software needed to integrate sensor readings and control.

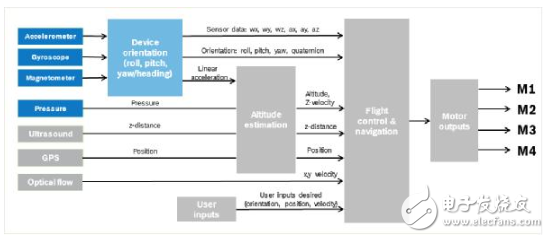

The figure below shows the different signal processing functions in a typical consumer drone. The left column shows the individual sensors and the right column shows the derived software processing functions, such as positioning processing and flight control algorithms. The deep blue sensor module represents the most advanced sensor, primarily for the stability of indoor and toy drones, and the gray sensor module represents the extended optional features required for outdoor flight and automatic waypoint navigation.

With integrated sensors, certain software features, such as location processing, can be performed directly on the chip by primarily incorporating various sensor readings. For drone manufacturers, this can significantly reduce the complexity of engineering and software, avoid unnecessary risks and reduce time-to-market. However, manufacturers still need to provide their own software, especially the mechanical design and dynamics-specific code of the drone, such as control loops and use case specific functions.

Overview of signal processing for consumer drones

Typical drone function

Let's take a look at how innovative MEMS sensor technology can be combined with software to implement modern drone functions.

Even in low-cost toy drones, complex functions are still very common today. First, the stabilizer uses the IMU output to keep the drone in a horizontal position. By integrating data from the air pressure sensor to keep the drone at its height and position, for example in a toy application, the drone can be flipped without changing height. As a result, the pilot does not need hours of practice to master the basic movements and significantly reduces the risk of accidental collisions.

The data fusion with the GPS module provides some interesting outdoor flight functions for the drone, such as autonomous flight between multiple waypoints, and the “return home” function, ie the drone automatically returns to its starting position and falls safely. .

Other newer features include "track mode" or "follow me mode", which is the ability of a drone to rotate around a specific point or to have autonomous personnel tracking. By combining the camera, the pilot can now observe itself from a bird's eye view, while walking with a drone, and even interacting with the drone through gestures.

Unrestrained

The development of robotics, semiconductors, and today's MEMS sensors—including their ever-increasing precision and miniaturization—indicates the future of unmanned remote-controlled aircraft. From weather or pollution monitoring, livestock management, security or delivery systems to next-generation augmented reality games or IoT platforms, high-tech aircraft and drones will play an increasingly important role in our daily lives.

Pre:Internet of Things drives the rapid development of sensor technology 2025-12-30

Next:Application of various types of sensors in hydropower plants 2025-12-30

Collect

Collect

Navigate:

Navigate: