News

Industrial

Classification of wheel speed sensors and analysis of working principle

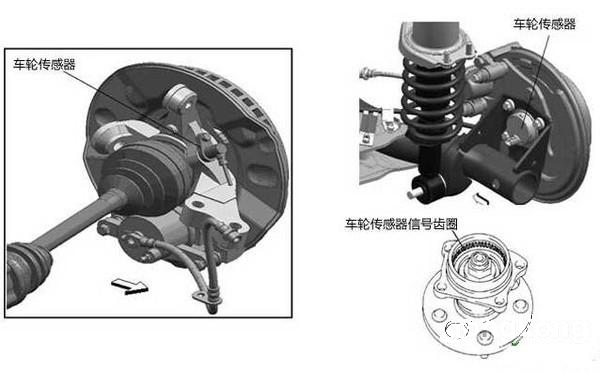

Wheel speed sensor is a sensor used to measure the wheel speed of a car.

For modern cars, wheel speed information is essential. Vehicle dynamic control systems (VDC), automotive electronic stability programs (ESP), anti-lock braking systems (ABS), and automatic transmission control systems all require wheels. Speed information. So wheel speed sensor is one of the most critical sensors in modern cars.

Generally speaking, all speed sensors can be used as wheel speed sensors, but considering practical factors such as the working environment of the wheels and the size of the space, the commonly used wheel speed sensors are: magnetoelectric wheel speed sensors, hall wheel speed sensors .

Magnetoelectric wheel speed sensor

The magneto-electric wheel speed sensor is designed using the principle of electromagnetic induction, and its main components are shown in the figure below.

It has the characteristics of simple structure, low cost, no fear of mud and dirt, etc. It is widely used in the ABS anti-lock braking system of modern cars.

But magnetoelectric wheel speed sensors also have some disadvantages:

(1) The frequency response is not high. When the vehicle speed is too high, the frequency response of the sensor cannot keep up, and it is easy to generate false signals;

(2) Poor ability to resist electromagnetic interference, especially when the amplitude of the output signal is small.

Hall wheel speed sensor

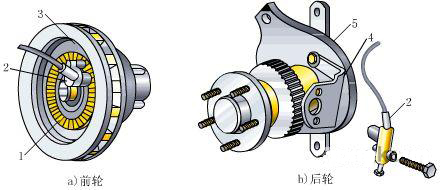

The Hall-type wheel speed sensor is made using the Hall effect principle, as shown in the figure below. Hall-type wheel speed sensors have also been used in automobiles.

Hall type wheel speed sensor has the following characteristics:

(1) The amplitude of the output signal voltage is not affected by the speed;

(2) High frequency response;

(3) Strong resistance to electromagnetic wave interference.

How the wheel speed sensor works

The wheel speed sensor is composed of a permanent magnet, a magnetic pole, a coil and a ring gear. (See the figure below) When the ring gear 5 rotates in a magnetic field, the gap between the ring gear tip and the electrode changes at a certain speed, which changes the magnetic resistance in the magnetic circuit. As a result, the magnetic flux is increased and decreased periodically, an induced voltage proportional to the magnetic flux increase and decrease speed is generated at both ends of the coil 1, and the AC voltage signal is transmitted to the electronic controller.

(1) the value is not affected by the speed;

(2) High frequency response;

(3) Strong resistance to electromagnetic wave interference.

How the wheel speed sensor works

The wheel speed sensor is composed of a permanent magnet, a magnetic pole, a coil and a ring gear. (See the figure below) When the ring gear 5 rotates in a magnetic field, the gap between the ring gear tip and the electrode changes at a certain speed, which changes the magnetic resistance in the magnetic circuit. As a result, the magnetic flux is increased and decreased periodically, an induced voltage proportional to the magnetic flux increase and decrease speed is generated at both ends of the coil 1, and the AC voltage signal is transmitted to the electronic controller.

Pre:How to implement a maintenance-free sensor node 2026-02-05

Next:Nine-axis sensor principle and application analysis 2026-02-05

Collect

Collect

Navigate:

Navigate: