News

Industrial

Scientists invent multi-function 3D printed plastic composite sensor capable of detecting trace water

Recently, a team of Spanish and Israeli scientists led by Pilar Amo Ochoa of the Autonomous University of Madrid (UAM) developed a versatile 3D printed plastic composite sensor capable of detecting trace amounts of water. The 3D printable material is non-toxic and changes color from purple to blue under wet conditions.

“It is important to know how much water is present in a particular environment or material,” explains DESY scientist Michael Wharmby. “For example, if the oil contains too much water, the machine may not be well lubricated. If the fuel contains too much water, it may not burn properly.”

The scientist's new sensor material is a so-called copper-based coordination polymer, a compound in which water molecules bind to central copper atoms. They use Deutsches Elektronen

Synchrotron (DESY) source PETRA III was used to analyze changes in material during heating. “When the compound is heated to 60 degrees Celsius, the color changes from blue to purple.” Pilar

Amo Ochoa reports. The material is heated to 60 ° C to remove water molecules bound to the copper atoms, eventually causing a color change. “This change can be reversed by placing it in the air, placing it in water, or placing it in a solvent containing traces of water.”

“After understanding this, we are able to model the physical model of this change.” Jose Ignacio of the Institute of Materials Science (ICMM-CSIC)

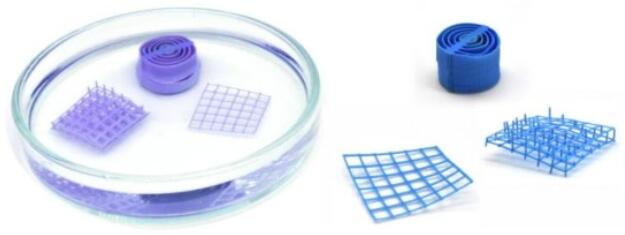

Martinez explained. The scientists then mixed the copper compounds into 3D printing inks and printed the sensors in several different shapes, which were tested in air and water. These tests show that 3D printed objects are more sensitive to water than to the compound itself. In the solvent, the printing sensor can detect 0.3% to 4% of water in less than two minutes.

If dried in an anhydrous solvent or dried by heating, the material turns back to purple. Detailed investigations have shown that the material is stable even in many heating cycles and that the copper compound is evenly distributed throughout the printed sensor. In addition, the material is stable in air for at least one year and is also 5 to 7 in the biologically relevant pH range.

“This work demonstrates the first 3D printed composite made from non-porous coordination polymers,” said Felix Zamora, co-author of the Autonomous University of Madrid. "In the field of functional 3D printing, it opens the door to the use of this large series of compounds that are easy to synthesize and have interesting magnetic, electrical and optical properties."

As scientists wrote in the journal Advanced Functional Materials, this development opens the door to the creation of a new generation of 3D printing functional materials.

Collect

Collect

Navigate:

Navigate: