News

Industrial

How to choose the right light sensor

The application of light sensors is very common. From the portable consumer market (smartphones, PDAs, desktop PCs and portable music players, etc.) to the consumer TV market (including LCD, plasma, rear projection and CRT TVs) to the medical, industrial and automotive markets, Sensors are everywhere. Some applications, such as bar code readers, laser printers, and autofocus microscopes use optically-detected reflected light to sense position; other applications, such as digital cameras, cell phones, and notebook computers, use optical sensors to measure The amount of ambient light.

System products with ambient light sensors provide a more comfortable display quality. This is very important for some applications. For example, car dashboards require a clear display in all ambient light conditions. During the day, users need maximum brightness to achieve optimal visibility, but this brightness is too dazzling at night.

Light sensors bring many benefits to portable applications. A system with a light sensor that automatically detects changes in conditions and adjusts the display settings to ensure optimal brightness of the display, which in turn reduces overall power consumption. For example, mobile phones, laptops, and digital cameras can automatically control the brightness of the display by using an ambient light sensor to extend battery life.

Photodiode is the best way to achieve

The photosensor includes a photoresistor, a phototransistor or a photodiode. Among them, the simplest light sensor is a photoresistor. Low-side photoresistors are made of CdS (cadmium sulfide) materials, while relatively expensive photoresistors are made of GaAs materials. The band gap of GaAs is small. It absorbs low-energy photons in infrared light and allows electrons to transition to the conduction band. Its illuminance ranges from 1 lux to 100 lux.

The complexity of photodiodes is higher. Photons bombard the semiconductor junction and generate current. A reverse bias is applied to the photodiode. A large reverse bias increases the sensor's sensing speed and linearity, but also increases the sensor's dark current and shot noise. Photon bombardment of the semiconductor junction will produce a forward current that reduces the reverse bias current. In the design, an external circuit can be added to the photodiode to linearize the I-V curve.

The general characteristics of phototransistors are the same as for photodiodes, but with the addition of amplification. It requires a larger bias current, but the noise associated with the current forces the sensitivity of the sensor to shift to a higher lux range of 1000 lux to 100,000 lux. The phototransistor's detection response time is similar to that of a photodiode and can be adjusted with a bias current. The bias current can also vary with the level of the detected signal. Phototransistors can roughly determine ambient light levels, such as indoor/outdoor, day/night, and bright light/shadow, so an external circuit is required to calibrate the output signal.

Currently, IC-based monolithic photodiodes are one of the best implementations of optical sensors. The photodiode is made of single crystal silicon. A typical sensor application component includes a photodiode, a current amplifier, and a passive low-pass filter. For the end user, it is important to be able to integrate all of these devices into one small package.

Six indicators of light sensors

When choosing a light sensor, the most important point is to understand which specification parameters are the most critical. In general, when selecting a light sensor, the important factors to be considered include spectral response/IR suppression, maximum lux count, photosensitivity, integrated signal conditioning, power consumption, and package size. The specific description of these six specifications is as follows:

Spectral Response / IR Suppression: Ambient light sensors should only be sensitive to the 400 nm to 700 nm spectrum.

Maximum lux number: Most applications are 10,000 lux.

Photosensitivity: Depending on the lens type of the light sensor, the light attenuation can be between 25% and 50% after passing through the lens. Low sensitivity is critical (5 lux) and you must choose a light sensor that can operate within this range.

Integrated signal conditioning (ie amplifier and ADC): Some sensors may offer a very small package, but require an external amplifier or passive component to get the desired output signal. Optical sensors with higher integration eliminate the need for external components (ADCs, amplifiers, resistors, capacitors, etc.) and have additional advantages.

Power consumption: For optical sensors that are subject to high lux ("10,000 lux"), it is best to use a non-linear analog output or a digital output.

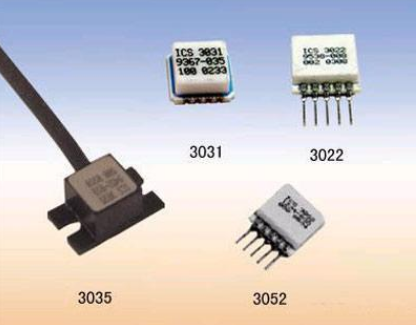

Package Size: For most applications, the package size is as small as possible. The smaller package sizes available today are approximately 2.0 mm x 2.1 mm. The 4-pin package measuring 1.3mm x 1.5mm is the next generation package.

Once the above important specification parameters have been determined, the next issue to consider is which type of output signal contributes to the implementation of the target application.

For most light sensors, the most common output is a linear analog output. While this output is ideal for some applications, the product now offers more output options, including linear voltage output, digital output (via I2C interface) or non-linear current or voltage output. Each output has certain advantages.

Collect

Collect

Navigate:

Navigate: