Hall Effect ICs

Hall Element

MR Sensors

Hall Current Sensors

Speedometer Sensors

Flow Sensors

LED Flashlights

PI Latches

- Production

- Technology

- Configuration

- Download

Production:

DATASHEET PDF![]()

90248.pdf

Features and Benefits

Micropower consumption ideal for battery-

powered applications

Omnipolar, easy to use as output switches

with both North and South pole

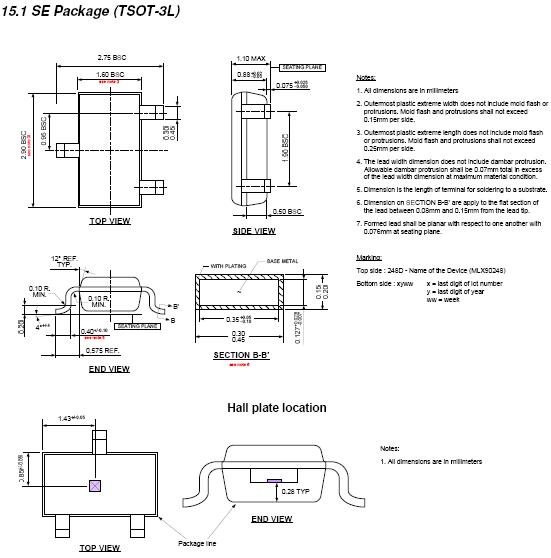

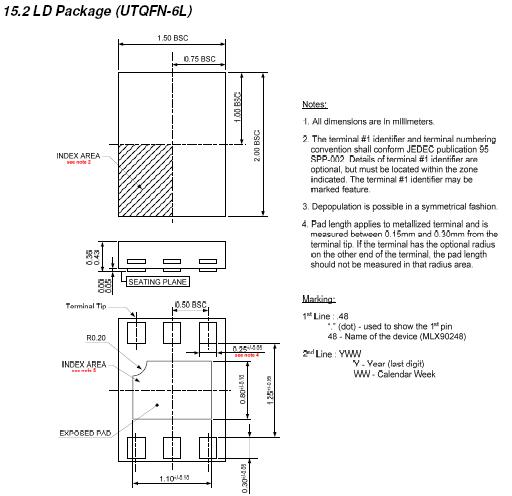

Ultra-Thin QFN package (0。43mm max) &

Thin SOT23 3L (both RoHS Compliant)

Very High Sensitivity Hall Sensor

Chopper stabilized amplifier stage

Operation down to 2。5V

Application Examples

Solid State Switch

Handheld Wireless Handset Awake Switch

Lid close sensor for battery-powered devices

Magnet proximity sensor for reed switch

replacement in low duty cycle applications

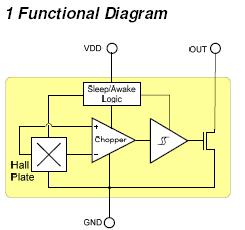

2 General Description

The MLX90248 OmnipolarTM Hall effect sensor IC

is fabricated from mixed signal CMOS technology。

It incorporates advanced chopper-stabilization

techniques to provide accurate and stable

magnetic switch points。

The circuit design provides an internally controlled

clocking mechanism to cycle power to the Hall

element and analog signal processing circuits。

This serves to place the high current-consuming

portions of the circuit into a “Sleep” mode。

Periodically the device is “Awakened” by this

internal logic and the magnetic flux from the Hall

element is evaluated against the predefined

thresholds。 If the flux density is above or below the

Bop/Brp thresholds then the output transistor is

driven to change states accordingly。 While in the

“Sleep” cycle the output transistor is latched in its

previous state。 The design has been optimized for

service in applications requiring extended

operating lifetime in battery powered systems。

The output transistor of the 90248 will be latched

on (BOP) in the presence of a sufficiently strong

South or North magnetic field facing the marked

side of the package。 The output will be latched off

(BRP) in the absence of a magnetic field。

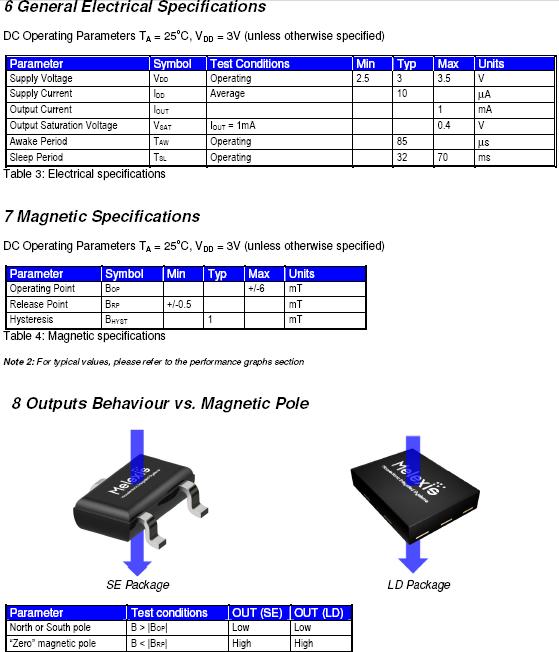

9 Detailed General Description

MLX90248

Micropower & Omnipolar? Hall Switch

The MLX90248 is originally used in mobile phone applications for open/close lid detection (slide and jack-

knife phone type)。 The goal of this detection is to switch on or off the application if the lid is opened or closed,

in order to save battery power。

The same operation principle can be simply applied to any other battery-powered device with a lid/cover like

laptop, digital cameras and camcorders。

By the use of a very high sensitivity Hall sensor, a very small and cheap magnet is enough to trigger the

MLX90248, hence it can easily replace reed switch。

The major benefit of using a Hall sensor is to provide “electronic” commutation, which is bounce-free, more

reliable and with increased lifetime compared to usual mechanical contacts。

10 Unique Features

The MLX90248 exhibits “Omnipolar” magnetic characteristics。 It means the device reacts to both North and

South magnetic pole。 The purpose is to detect the presence of any magnetic field applied on the device。

This mode of operation simplifies customer production processes by avoiding the need to detect the Hall

sensor pole active on the magnet used in the application。

Taking the example of a generic Hall sensor “south pole active”, during its production, the customer must

detect the south pole of the application magnet and face it to the device to enable the output to be turned on

and off。 Without any magnet pole detection system, the incorrect magnetic pole (north in this example) could

be faced to the device which would fail the application。

Therefore, the “Omnipolar” magnetic behaviour helps customers by removing the need of magnet pole

detection system during production phase。

The “Micropower” feature makes the MLX90248 especially suitable for battery-powered device as it combines

low voltage operation and low current consumption。 By using a sleep/awake strategy managed internally, the

power consumption is drastically reduced。 To make a comparison, the MLX90248 consumes 100 times less

power than the generic low voltage Melexis Hall sensor US3881。

As well as Thin SOT package, the MLX90248 is now delivered in an ultra thin UTQFN package。 This new

leadless package only requires 3mm2 PCB surface and is 0。43mm maximum thick, which is particularly

important in design where space-saving and miniaturisation are the critical factors。

13 Standard information regarding manufacturability of Melexis

products with different soldering processes

Our products are classified and qualified regarding soldering technology, solderability and moisture sensitivity

level according to following test methods:

Reflow Soldering SMD’s (Surface Mount Devices)

? IPC/JEDEC J-STD-020

Moisture/Reflow Sensitivity Classification for Nonhermetic Solid State Surface Mount Devices

(classification reflow profiles according to table 5-2)

? EIA/JEDEC JESD22-A113

Preconditioning of Nonhermetic Surface Mount Devices Prior to Reliability Testing

(reflow profiles according to table 2)

Wave Soldering SMD’s (Surface Mount Devices) and THD’s (Through Hole Devices)

? EN60749-20

Resistance of plastic- encapsulated SMD’s to combined effect of moisture and soldering heat

? EIA/JEDEC JESD22-B106 and EN60749-15

Resistance to soldering temperature for through-hole mounted devices

Iron Soldering THD’s (Through Hole Devices)

? EN60749-15

Resistance to soldering temperature for through-hole mounted devices

Solderability SMD’s (Surface Mount Devices) and THD’s (Through Hole Devices)

? EIA/JEDEC JESD22-B102 and EN60749-21

Solderability

For all soldering technologies deviating from above mentioned standard conditions (regarding peak

temperature, temperature gradient, temperature profile etc) additional classification and qualification tests

have to be agreed upon with Melexis。

The application of Wave Soldering for SMD’s is allowed only after consulting Melexis regarding assurance of

adhesive strength between device and board。

Melexis is contributing to global environmental conservation by promoting lead free solutions。 For more

information on qualifications of RoHS compliant products (RoHS = European directive on the Restriction Of

the use of certain Hazardous Substances) please visit the quality page on our website:

http://www。melexis。com/quality。aspx

14 ESD Precautions

Electronic semiconductor products are sensitive to Electro Static Discharge (ESD)。

Always observe Electro Static Discharge control procedures whenever handling semiconductor products

Contact person:

Frances New

Phone:+86-755-81832961

Fax:+86-755-83299282

Email:sumzi@sumzi.com

MSN:sumzi_frances@msn.com

http://www.sumzi.com

Collect

Collect

Navigate:

Navigate:

Description:

Description: print

print tel:0755-83031813

tel:0755-83031813 email:sumzi@sumzi.com

email:sumzi@sumzi.com