Hall Effect ICs

Hall Element

MR Sensors

Hall Current Sensors

Speedometer Sensors

Flow Sensors

LED Flashlights

PI Latches

- Production

- Technology

- Configuration

- Download

Production:

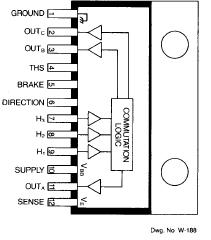

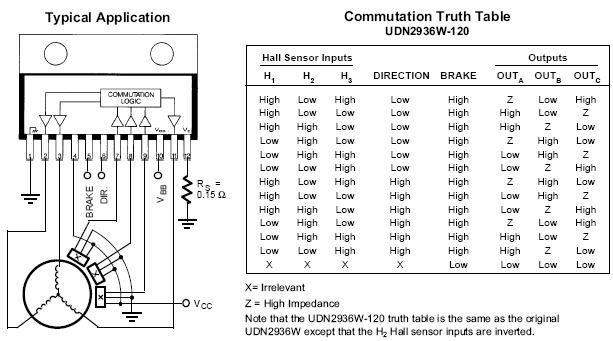

Combining logic and power, the UDN2936W-120 provides com-

mutation and drive for three-phase brushless dc motors. Each of the

three outputs are rated at 45 V and ±2 A (±3 A peak), and include

internal ground clamp and flyback diodes. The driver also features

internal commutation logic, PWM current control, and thermal shut-

down protection.

The UDN2936W-120 is compatible with single-ended digital or

linear Hall effect sensors. The commutating logic is programmed for

120° electrical separation. The UDN2936W-120 can replace the

original UDN2936W (60° electrical separation) by simply adding an

inverter at the H2 input. Current control is accomplished by sensing

current through an external sense resistor and pulse-width modulating

the source drivers. Voltage thresholds and hysteresis can be externally

set by the user. If desired, internal threshold and hysteresis defaults

(300 mV, 7.5 percent) can be used. The UDN2936W-120 also includes

braking and direction control. Internal protection circuitry prevents

crossover current when braking or changing direction.

The UDN2936W-120 is also available for operation between -40°C

and +85°C. To order, change the prefix from ‘UDN’ to ‘UDQ’.

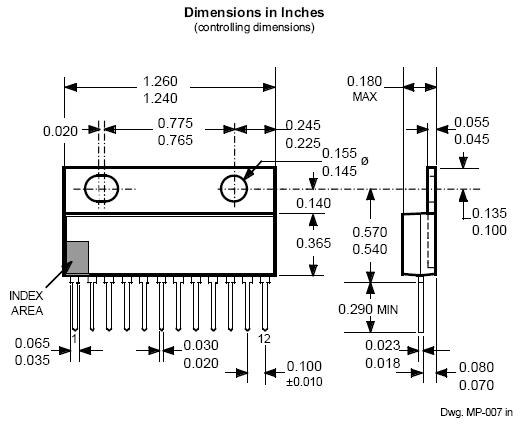

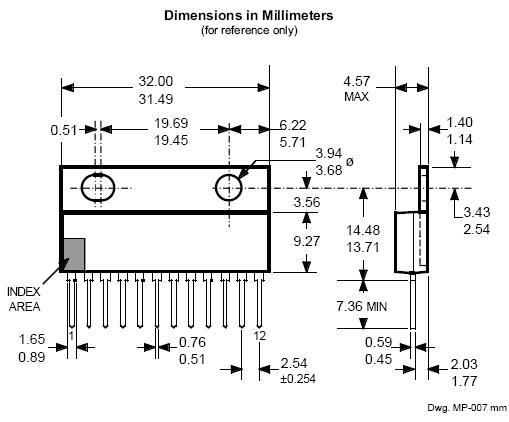

For maximum power-handling capability, the UDN2936W-120 is

supplied in 12-pin single in-line power-tab package. An external heat

sink may be required for high-current applications. The tab is at

ground potential and needs no insulation.

FEATURES

■ 10 V to 45 V Operation

■ ±3 A Peak Output Current

■ Internal Clamp Diodes

■ Internal PWM Current Control

■ 120° Commutation Decoding Logic

■ Thermal Shutdown Protection

■ Compatible with Single-Ended or Differential Hall-Effect Sensors

■ Braking and Direction Control

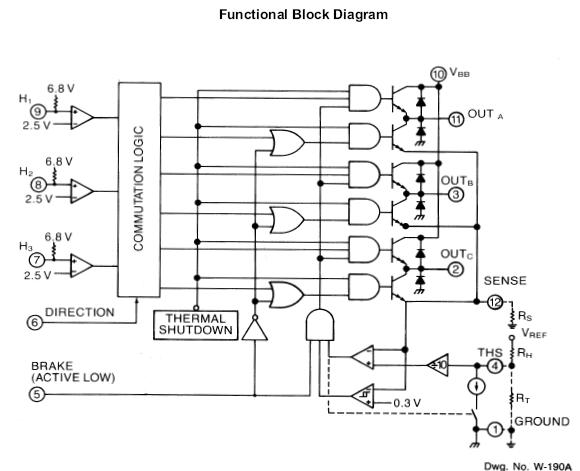

The UDN2936W-120 power driver provides commutation

logic and power outputs to drive three-phase brushless dc

motors.

The UDN2936W-120 is designed to interface with single-

ended linear or digital Hall-effect devices (HEDs). Internal

pull-up resistors allow for direct use with open-collector digital

HEDs. The Hn inputs have 2.5 V thresholds.

The commutation logic provides decoding for HEDs with

120° electrical separation. At any one step in the logic sequenc-

ing, one half-bridge driver is sourcing current, one driver is

sinking current, and one driver is in a high-impedance state (see

Truth Table).

A logic low on the BRAKE pin turns on the three sink

drivers and turns off the three source drivers, essentially

shorting the motor windings to ground. During braking, the

back-electromotive force generated by the motor produces a

current that dynamically brakes the motor. Depending upon the

rotational velocity of the motor, this current can approach the

locked rotor current level (which is limited only by the motor

winding resistance). During braking, the output current-

limiting circuitry is disabled and care should be taken to ensure

that the back-EMF generated brake current does not exceed the

maximum rating (3 A peak) of the sink drivers and ground

clamp diodes.

Changing the logic level of the DIRECTION pin inverts the

output states, thus reversing the direction of the motor. Chang-

ing the direction of a rotating motor produces a back-EMF

current similar to when braking the motor. The load current

should not be allowed to exceed the maximum rating (±3 A

peak) of the drivers.

An internally generated dead time (td) of approximately

2 µs prevents potentially destructive crossover currents that can

occur when changing direction or braking.

Motor current is internally controlled by pulse-width

modulating the source drivers with a preset hysteresis format.

Load current through an external sense resistor (RS) is con-

stantly monitored. When the current reaches the set trip point

(determined by an external reference voltage or internal

default), the source driver is disabled. Current recirculates

through the ground clamp diode, motor winding, and sink

driver. An internal constant-current sink reduces the trip point

(hysteresis). When the decaying current reaches this lower

threshold, the source driver is enabled again and the cycle

repeats

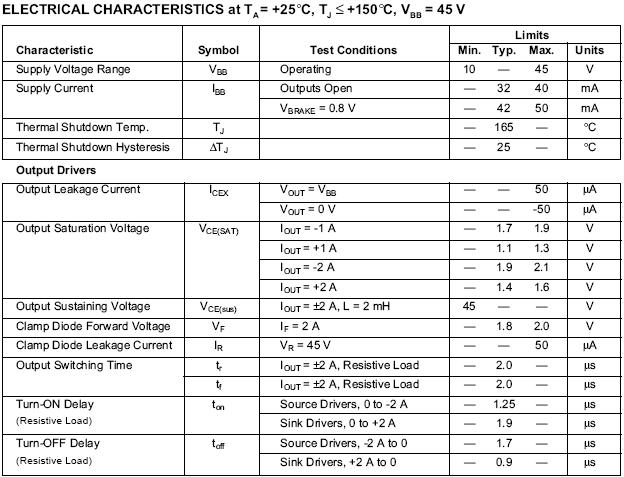

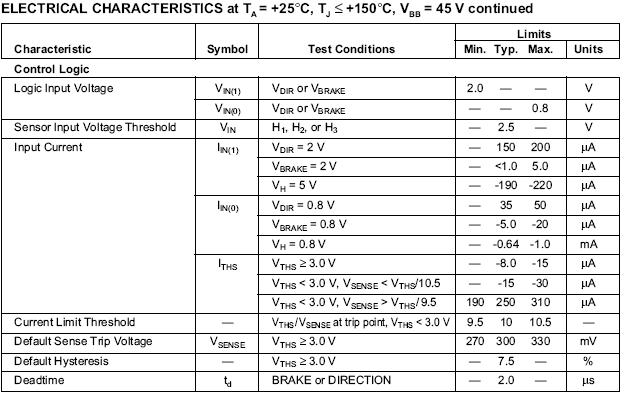

Thresholds and hysteresis can be set with external resistors,

or internal defaults can be used. With VTHS > 3.0 V, the trip

point is internally set at 300 mV with 7.5% hysteresis. Load

current is then determined by the equation:

ITRIP = 0.3 / RS

With VTHS < 3.0 V, the threshold, hysteresis percentage,

and peak current are set with external resistors according to the

equations:

threshold voltage (VTHS) = VREF x RT /(RH + RT)

hysteresis percentage = RH/50 VREF

load trip current (ITRIP) = VTHS/10 RS

Percentage hysteresis is a fixed value independent of load

current. The chopping frequency is a function of circuit

parameters including load inductance, load resistance, supply

voltage, hysteresis, and switching speed of the drivers.

The UDN2936W-120 outputs are rated for normal operat-

ing currents of up to ±2 A and startup currents to ±3 A (see

cautions above regarding braking and changing of motor

direction). Internal power ground-clamp and flyback diodes

protect the outputs from the voltage transients that occur when

switching inductive loads. All devices also feature thermal

protection circuitry. If the junction temperature reaches

+165°C, the thermal shutdown circuitry turns off all output

drivers. The outputs are re-enabled when the junction cools

down to approximately +140°C. This protection is only

intended to protect the device from failures due to excessive

junction temperature or loss of heat sinking and should not

imply that output short circuits are permitted.

As with all high-power integrated circuits, the printed

wiring board should utilize a heavy ground plane. For optimum

performance, the drivers should be soldered directly into the

board. The power supply should be decoupled with an electro-

lytic capacitor (>10 µF) as close as possible to the device

supply pin (VBB).

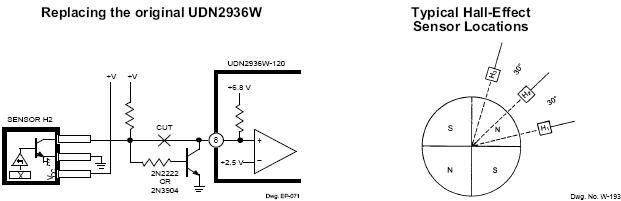

Replacing the UDN2936W. The original UDN2936W can

be easily replaced with a UDN2936W-120 by inserting an

inverter (two resistors and a 2N3904 or 2N2222) between the

H2 Hall sensor and pin 8 of the UDN2936W-120, as shown in

the figure on the next page. If an extra inverter is available, be

certain that a pull-up for the Hall sensor is provided.

Contact person:

Frances New

Phone:+86-755-81832961

Fax:+86-755-83299282

Email:sumzi@sumzi.com

MSN:sumzi_frances@msn.com

http://www.sumzi.com

Collect

Collect

Navigate:

Navigate: Description:

Description: print

print tel:0755-83031813

tel:0755-83031813 email:sumzi@sumzi.com

email:sumzi@sumzi.com